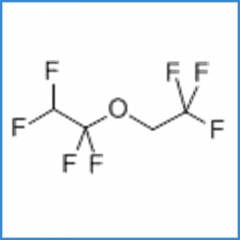

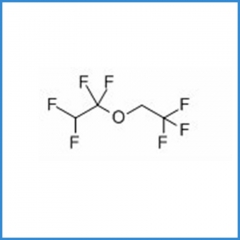

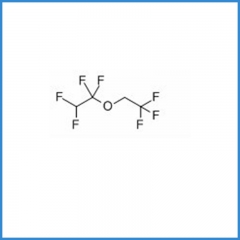

1,1, 2 ,2-Tetrafluoroethyl 2 ,2, 2-trifluoroethyl ether CAS 406-78-0

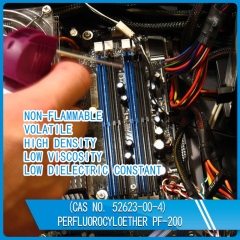

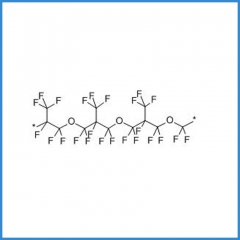

Factory Price 1,1,2,2-Tetrafluoroethyl 2,2,2-trifluoroethyl ether CAS 406-78-0 with purity 99%Min Colorless Clear Liquid Product Name: 1,1,2,2-Tetrafluoroethyl 2,2,2-trifluoroethyl ether Synonyms: Hydrofluoroether(HFE-347); CAS: 406-78-0 Classification:detergent Molecular formual:CF3CH2OCF2CF2H Place of Origin:Anhui, China Purity:99% Min Application:Solvent Appearance:Colorless Clear Liquid Color:Colorless Clear Form:Liquid Density:1.487

read more