2018-03-26

1. acrylic water-based paint The use of acrylic emulsion as the main component, the main feature is good adhesion, will not deepen the color of wood, but the wear resistance and chemical resistance is poor, the film hardness is soft, fullness is poor, comprehensive performance in general, film Good construction is easy to produce defects. It is suitable for water-based wood primer, matte finish. Because of its low cost and low technical content, is the majority of low-end water-based paint business to market the main products. This is also the reason why most people think that water-based paint is not good. 2. acrylic and polyurethane synthesis Its characteristics in addition to adhering to the characteristics of acrylic paint, but also increased the wear and anti-chemical characteristics of the strong, better film hardness, comprehensive performance close to oily paint. Is the country's water-based paint to the development of the backbone. 3. pure polyurethane water-based paint Its comprehensive performance, fullness, high hardness, high hardness, wear resistance even more than oily paint, service life, color deployment has obvious advantages. Is a high-end products in the water-based wood paint, suitable for high-grade solid wood furniture, the price is relatively high. Water-based wood paint according to its film can be divided into three categories: 1. One-component water-based wood paint Advantages: one-component water-based paint through continuous improvement, its performance is getting better and better, in the original film flexible, high transparency, fast drying, good adhesion, delicate film on the basis of soft, the film fullness, water Resistance, hardness and scratch resistance are also significantly improved, fully able to meet the wooden furniture plane and facade system coating needs. At present, one-component water-based wood paint in children's pine furniture, children's toys, outdoor furniture, the application has been very mature. Disadvantages: water-based paint with water as a thinner, in the course of use will change the moisture content of wood, wood moisture content changes will lead to wood swelling, bending deformation, thus increasing the difficulty of water-based paint construction. In addition, water-based paint for thinner, made open and semi-closed effect, and thus in the processing of grinding to be more sophisticated, which requires furniture companies need to have a higher production process standards. As a single component of water-based paint by the natural evaporation of water film, so the construction temperature and humidity have certain requirements, and the film dry speed is slow, the degree of cross-linking is not high formation of the film is not dense, the final film Quality is not guaranteed, so the one-component water-based paint film hardness and scratch resistance is not strong. So the one-component water-based wood paint is not suitable for painting on the hardness requirements of high furniture....

read more

2019-09-04

Characteristics of water-based pressure-sensitive adhesive: 1. Diluted with deionized water 2. At room temperature (25 ~ 30 ℃), the glue sizing 24 hours after the bonding force to reach the maximum, can be tested. At low temperatures, the glue drying time is longer, should be based on the actual situation after the test time or sizing as much as possible after the use of heating baking (temperature 35 ~ 45 ℃) to ensure that the performance of the plastic. 3. Touch the skin with water or soap can be cleaned. 4. Not suitable: bonding material; PE, PP without surface treatment; soft salted plastic, fluorine resin, silicone resin; the surface is not rust treatment of iron, copper and other easy to rust the metal. 5. Manual sizing and sizing equipment, also applies to screen printing.

read more

2018-03-01

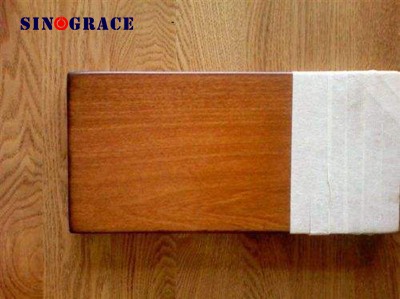

With the progress of water-based resin technology, water-based paint technology has been recognized by more and more industries and applications. In promoting environmental protection at the same time, water-based paint its special hydrophilic structure may also lead to premature failure of the coating. We usually attribute the cause of failure to resin performance defects, while ignoring the water-based paint and the bonding between the substrate. The binding force can be understood as a good connection between the coating and the substrate. The experimenter has obtained the connection between the coating and the substrate by various methods, but the coating does not completely wet the substrate to form a solid-liquid interface Before the discussion of mechanical anchoring, van der Waals force or chemical bond and other factors will become unrealistic. Therefore, "wetting spread" has become a prerequisite for the combination of factors. In everyday applications, it is generally believed that relatively rough substrates are more conducive to the formation of binding forces. Theoretically, the surface of the rough substrate has a larger surface area than the flat substrate, and when the substrate is wetted with the coating, the air is removed and both have a larger contact area to obtain the bonding force. However, for waterborne coatings, the surface tension of 40-50 dyn / cm is higher than that of most substrates, and the contact area of the aqueous coating with the substrate is often reduced due to the inability to wetting, resulting in loss of the binding force. For example, Figure 1 shows that the formation of liquid-solid interface is conducive to the formation of binding force. The water-based coating is in contact with the substrate. The gas-solid interface SG and the gas-liquid interface SL are replaced by the liquid-solid interface SG. The coating and the substrate begin to establish a part of the connection relationship. When this phenomenon is rapidly diffused to a certain extent, Into the drying curing stage, and finally complete the mechanical anchoring or chemical reaction. The angle of contact is related to the surface tension of the substrate and the coating. The angle is directly related to the degree of wetting and spreading of the aqueous coating to the substrate. When the contact angle θ> 90, it is considered that no wetting occurs, and the contact angle θ <90, the paint can quickly spread and penetrate the pores. When the ideal liquid-solid interface is formed, the increase of the contact area between the coating and the substrate must promote the formation of the binding force. However, due to the surface pressure difference, the complete wetting may only be achieved in large pore size pores, and for pores with small pore size, the wetting process becomes rather slow and tends to complete wetting before curing. When the tiny pores are sufficiently dense, a thin layer of air film is formed between the surface of the non...

read more

2018-01-16

Classification and quality requirements of BOPP sealing tape (including ordinary sealing tape, printing tape, high-viscosity antifreeze tape):The series of products mainly to polypropylene film, special polypropylene film, acrylic and water-based acrylic plastic as raw materials and has the characteristics of posting smooth. It is suitable for general packaging and fixed and packaging and fixed in ultra-low temperature environment. Widely used in the packaging of food, beverages and packaging business product in supermarkets, professional image packaging of quality and gifts, the closure in developed countries or environmental control areas.

read moreCopyright © 2015-2024 Anhui Sinograce Chemical Co., Ltd..All Rights Reserved.powered by dyyseo.com

top