perfluorooctanoic acid(CAS 335-67-1)FC-089

cas: 335-67-1

Name:

perfluorooctanoic acid;A 5717;Fluorad FC-26;Eftop EF 201;Octanoic acid, pentadecafluoro-;Perfluorocaprylic acid;perfluoro-n-octanoic acid;Pentadecafluorooctanoic Acid High Grade;IPC-PFFA-8 HG;PFOA,Perfluorocaprylic acid,Perfluorooctanoic acid;PERFLUOROOCTANOATE;Pfoa;RARECHEM AL BO 0424;Perfluorooctanoic acid;perfluorooctylcarboxylic acid;Perfluoroctanoic acid;PFOA,Perfluorocaprylic acid;Perfluorooctanoic Acid High Grade;[14C]-Perfluorooctanoic acid;Pentadecafluorooctanoic Acid;pentadecafluorocaprylic acid;EF 201;IPC-PFFA-8;

Brand:

sinograceitem no.:

FC-089Payment:

L/C、D/A、D/P、T/T、MoneyGram、Paypal other.product origin:

China AnhuiColor:

white or off-white powdershipping port:

Shanghai and other portsLead Time:

15-25 Days

inquire

Product Detail

Basic Information

cas: 335-67-1

Name:

perfluorooctanoic acid;A 5717;Fluorad FC-26;Eftop EF 201;Octanoic acid, pentadecafluoro-;Perfluorocaprylic acid;perfluoro-n-octanoic acid;Pentadecafluorooctanoic Acid High Grade;IPC-PFFA-8 HG;PFOA,Perfluorocaprylic acid,Perfluorooctanoic acid;PERFLUOROOCTANOATE;Pfoa;RARECHEM AL BO 0424;Perfluorooctanoic acid;perfluorooctylcarboxylic acid;Perfluoroctanoic acid;PFOA,Perfluorocaprylic acid;Perfluorooctanoic Acid High Grade;[14C]-Perfluorooctanoic acid;Pentadecafluorooctanoic Acid;pentadecafluorocaprylic acid;EF 201;IPC-PFFA-8;

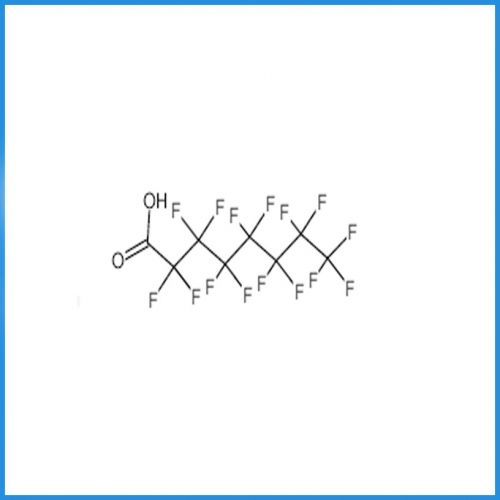

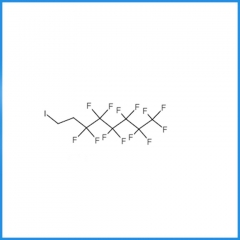

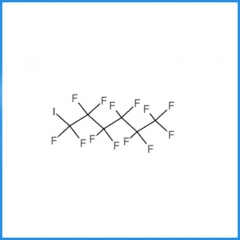

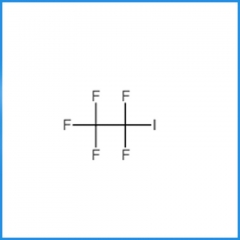

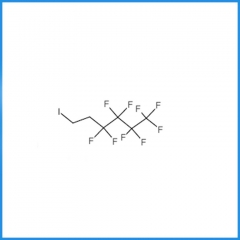

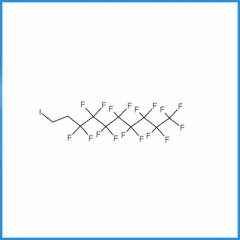

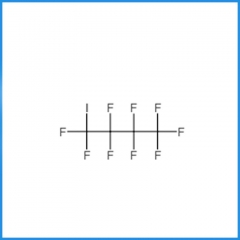

Molecular formula: C8HF15O2

Molecular weight: 414.06800

PSA: 37.30000

LOGP: 4.44510

Physical index

Appearance and properties: white or off-white powder

Density: 1,7 g/cm3

Boiling point: 189 °C736 mm Hg(lit.)

Melting point: 55-56 °C(lit.)

Flash point: 189-192°C

Refractive index: 1.387

Water solubility: 3.4 g/L

Stability: Stable. Incompatible with bases, oxidizing agents, reducing agents.

Storage conditions: 2-8ºC

Security Information

RTECS number: RH0781000

Safety instructions: S26-S36/37/39-S45-S36/37

WGK Germany: 2

Hazard category code: R34

Customs code: 29159080

Dangerous goods transport code: UN 3261 8/PG 3

Hazard category: 8

Packing level: III

Dangerous goods mark: C

Danger signs: GHS05, GHS07, GHS08

Hazard description: H302 + H332; H318; H351; H360D; H362; H372

Hazard prevention statement: P201; P260; P263; P280; P305 + P351 + P338 + P310; P308 + P313

Signal word: Danger

Production methods and application

production method

In the electrolytic cell of the electrode group composed of nickel anode and iron cathode alternately, anhydrous liquid hydrogen fluoride, octanoyl chloride and a small amount of n-butyl mercaptan are added, mixed evenly, and 2500A direct current is applied. In order to maintain the concentration of the electrolyte during the electrolysis process, octanoyl chloride must be continuously added. The electrolysis product is insoluble in the electrolyte and sinks to the bottom of the electrolytic cell, and needs to be released after a certain period of time. The electrolyte temperature is controlled at 24°C. The voltage is controlled between 5 and 8V for electrolysis operation. The gas produced in the electrolysis process is cooled and condensed to below -30℃ by the condenser, and then pressurized by the buffer and water to keep the system at a pressure of 0.042MPa, and then the gas is vented. The electrolysis product is neutralized by sodium hydroxide, acidified by sulfuric acid, and then sent to a rectification tower for rectification, and the fraction of 1.33kPa, 91.5-93.5℃ is collected as the finished product. Electrolysis: Esterification: 2. Put the raw material octanoyl chloride (purity 99.5%), hydrogen fluoride and a small amount of n-butyl sulfuric acid into the electrolytic cell, energize at 20~25℃ (voltage 5~8), and neutralize the electrolytic product with alkali, and then It is acidified with acid and distilled to obtain perfluorooctanoic acid.

use

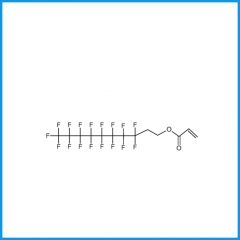

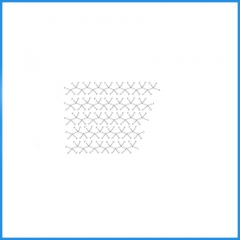

1. It is mainly used in the production of derivatives. Its sodium salt and ammonium salt are excellent dispersants for the synthesis of fluorine-containing polymers such as polytetrafluoroethylene, 1# fluorine rubber, 2# fluorine rubber, its complexes and its acrylic acid synthesis The polymer is a good water and oil repellent, and its ester derivatives are used as a chromatographic stationary liquid.

English

English français

français русский

русский español

español العربية

العربية