Product Detail

Basic Information

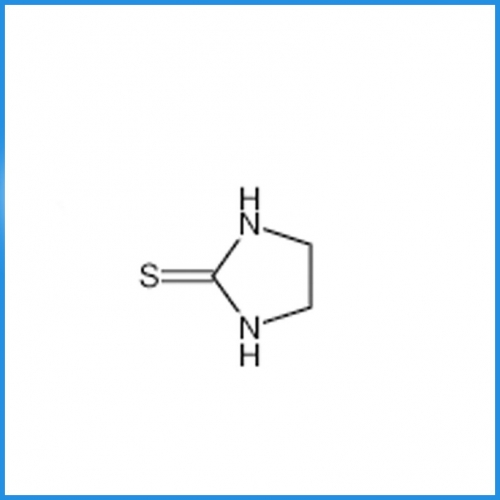

Cas: 96-45-7

Name: 2-Imidazolidinethione,NA 22;ETU;ethylene thiourea;ACCEL-BF;mercazini;robac22;Mercozen;2-thioxo imidazolidine;2-Thioxoimidazolidine;N,N'-ethylenethiourea;2-imidazolidine-thione;NA-22-D;imidazoline -2-thione;

Molecular formula: C3H6N2S

Molecular weight: 102.15800

PSA: 56.15000

LOGP: 0.12170

Physical index

Appearance and properties: white to light green crystalline powder

Density: 1.41~1.45

Boiling point: 148.3ºC at 760 mmHg

Melting point: 196-200 °C(lit.)

Flash point: 252 °C

Refractive index: 1.664

Water solubility: 19 g/L (20 ºC)

Stability: Stable under normal temperatures and pressures.

Storage conditions: 0-6ºC

Security Information

RTECS number: NI9625000

Safety instructions: S53-S45

WGK Germany: 2

Hazard category code: R22; R61

Dangerous goods transport code: 2811

Customs code: 29332990

Hazard category: 6.1(b)

Packing level: III

Dangerous goods mark: T

Signal word: Danger

Hazard description: H302; H351; H360D; H372

Hazard prevention statement: P201; P281; P308 + P313

Danger signs: GHS07, GHS08

Production methods and application

production method

1. In the glass-lined reactor, add water and ethylenediamine, reduce the temperature by 20°C, add carbon disulfide, control at 35-40°C, react for 4 hours, heat up and recover carbon disulfide to generate vinyl dithiocarbamate. The vinyl dithiocarbamate is cooled to below 50°C, hydrochloric acid is added, and hydrogen sulfide is released when the temperature is raised, and cyclized to produce ethylene thiourea. In the cyclization reaction, acetic acid can also be used instead of hydrochloric acid for the reaction, and the obtained crude ethylene thiourea is dissolved in boiling water, filtered, cooled to precipitate crystals, dehydrated, dried, and pulverized to obtain the finished product. (Kg/ton) Ethylenediamine (70%) 740 Carbon disulfide (95%) 1250.

2. Put 24 kg of ethylenediamine, 48 kg of industrial alcohol, and 60 kg of distilled water into the reactor in turn. Under stirring, slowly add 32 kg CS2, and control the temperature at about 60 ℃ during the dropping process. After adding CS2, the temperature was raised to 100 ℃ and refluxed for 1 h. Then add 3.6 kg of concentrated hydrochloric acid and reflux for 9-10 h. Cool to crystallize. The product was obtained by suction filtration, washing and drying with acetone. The yield is about 80%-85%.

3. Using water as the reaction medium, carbon disulfide and ethylenediamine as raw materials to prepare ethylene thiourea (accelerator NA-22 or ETU), the reaction is carried out in two steps. ①Carbon disulfide undergoes addition reaction with ethylenediamine under the action of water to produce the intermediate product ethylamine for aminosulfuric acid: The second step is the cyclization of ethylamine for aminosulfuric acid under the action of water to obtain the final product ethylene sulfide Urea:

use

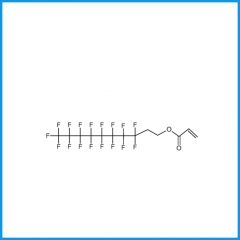

ETU is an overspeed accelerator used in chloroprene. Must be used together with zinc oxide and magnesium oxide. It vulcanizes well above 121°C. It can strengthen the tensile force of rubber, has low compression set, but has high elasticity and good anti-aging performance.

English

English français

français русский

русский español

español العربية

العربية