Product Detail

Description

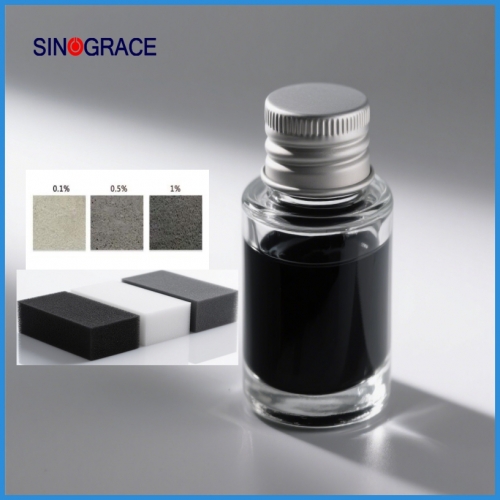

This product is a black macromolecular reactive colorant with bright and transparent color. This product has high color intensity, no migration, no precipitation, safer and more environmentally friendly, and can also give polyurethane or other thermoplastic products bright color effects

Typical Properties

|

Physical properties

|

Features

|

Value

|

Test Way

|

|

Appearance

|

Black liquid

|

/

|

Visual inspection

|

|

Color value(Abs/g/L)

|

/

|

|

GB/T11081-2005

|

|

PH

|

|

4-7

|

GB/T 9724-2007

|

|

Moisture(%)

|

|

≤2

|

EN13267-2001

|

|

Vicosity(mPa.s)

|

|

20000-50000

|

GB/T 11175-2002

|

|

Hydroxyl value

(mgKOH/g)

|

|

189

|

ASTM E 1899-08

|

Competitive Price Polyethylene Glycol-Based Lubricants and Coatings Ideal for Manufacturer

Product Performance

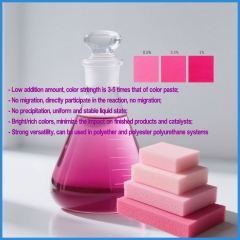

- Low addition amount, color strength is 3-5 times that of color paste;

- No migration, directly participate in the reaction, no migration;

- No precipitation, uniform and stable liquid state;

- Bright/rich colors, minimize the impact on finished products and catalysts;

- Strong versatility, can be used in polyether and polyester polyurethane systems

|

Light fastness

|

Heat resistance

|

|

150℃

|

200℃

|

|

●●●●●

|

ΔE*ab≈0.69

|

ΔE*ab≈1.22

|

|

Notes:

1. 3kg pressure,heat for 24h under 40℃and observe the migration(the conclusion is no color migration)

2. Observe chromatic aberration under sunlight after 1 week

3. 150℃ and 200℃ for 1h, observe the color difference.

●●●●●Excellent ●●●● Good ●●● Average

|

|

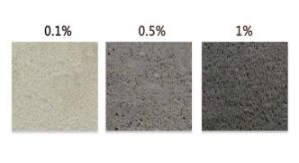

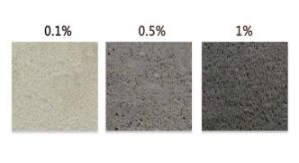

Different addition amount under nature sun

|

Application

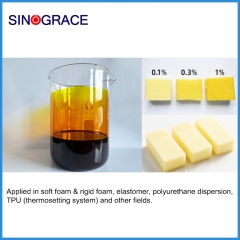

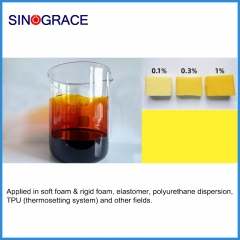

Applied in soft foam & rigid foam, elastomer, polyurethane dispersion, TPU (thermosetting system) and other fields.

Precautions for use

- Please keep the instrument clean to avoid cross-color resulting in color difference in the foaming process.

- Due to the presence of hydroxyl groups in the product, please take into account the influence of hydroxyl values when designing the foaming formula.

- After mixing with polyols that already contain amine catalysts or other active additives, it is recommended to use immediately and avoid prolonged storage as some additives may cause the mixture to fade.

- Before adding reactive dyes, it is necessary to carefully design the formula.

Application way

According to the actual effect and requirement, the reference addition amount is: light color dosage: 0.01%-0.1%, dark color dosage: 0.5%-1.5%

Storage and handling

- Shelf life: 24 months from manufacturing date

- Storage conditions: Store in a cool and dry place under sealed conditions, storage temperature 5-40℃,if the storage temperature is below 0℃, the colorant should be allowed to return to room temperature and stirred appropriately before use.

- Please handle with care during transportation and do not throw or drop.

- Package: 25kg/200kg barrel

English

English français

français русский

русский español

español العربية

العربية