|

l It

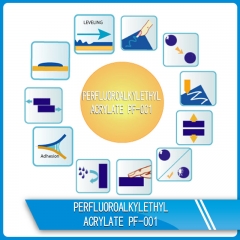

is very easy to copolymerize with other acrylate monomers in solution. Its

copolymer is particularly suitable for preparing coatings. Copolymerization

of dodecyl heptyl methacrylate with acrylic monomers for coatings can improve

the chemical stability and weather resistance of coatings. Hydrolytic

resistance, hydrophobic and oleophobic. This coating can form a coating with

good adhesion and strength during drying at room temperature

l It

can be copolymerized with monomers with active functional groups such as

(meth) acrylic acid, hydroxyacrylic acid ester, and hydroxyacrylamide to form

thermosetting copolymer resins containing reactive functional groups. This

resin can be used under the action of a crosslinking agent. Cured at room

temperature or lower. Because dodecyl heptyl methacrylate contains multiple

fluorine atoms, it has strong hydrophobicity, thereby reducing the phenomenon

of coating film chalking, cracking, and gloss reduction caused by monomer

hydrolysis. The addition of dodecafluoroheptyl methacrylate also greatly

improves the pollution resistance

l It

has properties close to typical acrylic monomers, and can also be used for

emulsion polymerization. As a fluorine-containing monomer,

l due

to the surface-active effect of fluorine, in order to improve the stability

of the emulsion during polymerization. Polymerization with fluorinated

emulsifiers

l It is difficult to polymerize dodecyl

heptyl methacrylate with light irradiation. It is particularly suitable for

copolymerization with certain UV polymerizing monomers, and the resulting

copolymer is used as a UV crosslinked resin.

l It can be used as a component of a

variety of special coatings. Due to its excellent chemical stability, this

compound is used as a protective coating for aircraft; it can also be

copolymerized with other vinyl compounds and propylene-based compounds for

use as Paper smooth coating, this coating is necessary to protect the surface

of printed paper and improve gloss, and improve the anti-blocking and

anti-break properties

l Can be used in the manufacture of

contact lenses, photocopying toners, optical fibers, pigments and coatings,

photosensitive resin materials, adhesives, medical equipment

|

English

English français

français русский

русский español

español العربية

العربية