How much do you know about self-adhesive printed labels

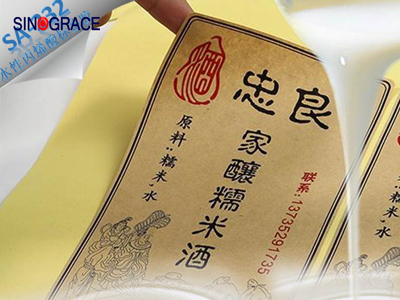

Self-adhesive refers to paper, film or other special materials as fabric, coated with adhesive on the back, a composite material printed with silicon protective paper as the base paper, the reason for the rapid rise of self-adhesive in recent years, because it is very practical, and very convenient, the cost is not high, the following to tell you about a few small knowledge of self-adhesive printing. Printing size Specifications and dimensions of self-adhesive printing labels, appearance, shape and color of products. According to the size of the product, the content needs to customize the size and shape style is very much, there are round, rectangular, square, rounded corner, irregular shape. To customize the shape and color to match the style characteristics of the product. Printing material Self-adhesive printing label material, the use of adhesive type. Some stickiness is strong, some stickiness is not strong, some can not tear, some can move, there are many kinds of self-adhesive labels, there are thermal paper, PET matte silver paper, coated paper, kraft paper, brushed self-adhesive stickers, transparent PVC stickers, water-soluble paper, etc. Common Uses The common uses of self-adhesive printing labels are customized according to the categories and nature of the products, such as trademarks, stickers, signs, inscription boards, etc., which are not only applied in food and beverage, daily necessities, household appliances, cultural and educational supplies, but also in the field of commodity circulation of price labels and clothing, textiles, medicine, cosmetics and other aspects. At present, our company's waterborne adhesive and and waterborne Label adhesive, has been put on the market, the market feedback is good, the performance is excellent, fully able to meet the complex needs of customers of various packaging structures. For example Description Water based pressure adhesive for paper materials SA-232H is an adhesive specially designed for reverse and various gravure coaters at higher converting speeds, for the production of general purpose paper labels or other pressure sensitive articles. Type Acrylic ester and vinyl ester copolymer dispersion Key Features -Non-yellowing -Wider application range -Very good bleeding resistance -Very good paper-aging resistance -Excellent balance of tack and shear -Higher productivity through high speed converting -Good temperature and aging resistance Typical Properties Appearance Milky white liquid pH 6.0-8.0 Solid content 54±1% Type of emulsion Anionic Viscosity (25℃) 200-300mPa·s Density (20℃) 1.02 g/cm3 Application -General purpose paper labels -Various single copper, mirror copper paper, mirror wet paper, thermal paper, mirror aluminum paper, aluminum foil label and advertising materials

read more

English

English français

français русский

русский español

español العربية

العربية

![[Packaging label] Uncovered no glue residue! Silky removable label](/uploadfile/news/2e98e2a7cca5f3a575682e357d06420d.jpg)