What benefits can nano coatings bring to businesses

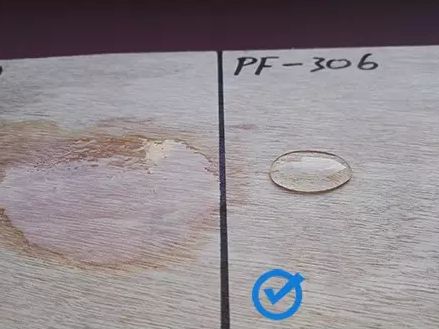

Nano coating is a very advanced process in recent years. This high-tech coating is not only non-toxic and harmless, but also can effectively prevent moisture and moisture erosion. What benefits can nano coating bring to businesses. Improving Product Quality Nano coating can protect the product from PCBA layer.Assuming no such protection, once liquid such as water or sweat enters, the product may be directly damaged, but with the protection of nano waterproof coating, from the most conservative theoretical point of view at least after watering, the user has enough time to deal with emergencies, open the shell, blow dry, etc., which equals first aid time. Increase sales highlights If you let consumers choose the same price or different configurations of the same model, the products with water, moisture and corrosion resistance will be more attractive. For mobile phones, for example, you can start the regular version and the waterproof version of a certain model.Waterproof version is absolutely necessary for many people to choose, waterproof becomes a key factor in the transaction. Reduce after-sale cost Based on the actual feedback from the users of the nano-coating, the original after-sale rate was reduced from a percentage to ten thousand parts.Some foreign single products need to travel by sea to other countries' ports coating can also protect products from sea humidity, salt fog and other factors to a certain extent. Enhance brand competitiveness Nano coatings effectively improve product durability, prolong service life, and reduce repair rate all of which naturally help the company to build a good reputation and enhance the competitiveness of the brand.Branding is not just about spending $2 on a media AD, it's about advertising.It will provide high-quality products and services for many years, leaving a good impression in the hearts of consumers once formed a good product brand impression, it will bring unlimited benefits for the enterprise. Our company produces nano superhydrophobic, which is used for building and wooden surface, car body, car glass and so on. Welcome to contact us, our email is sales@sinogracechem.com.

read more

English

English français

français русский

русский español

español العربية

العربية