Waterborne polyurethane dispersions have broad application prospects and the future demand will increase

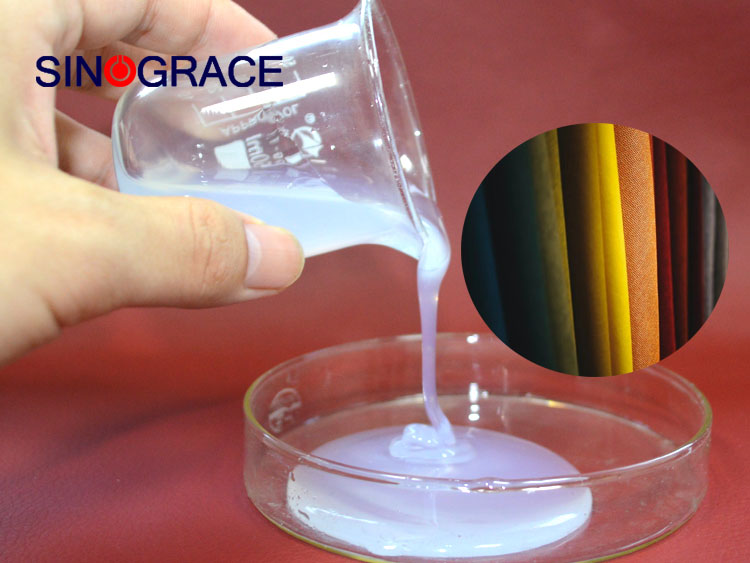

In the field of textile coatings, waterborne polyurethane dispersions can endow textiles with better wear resistance, flexibility, cleaning resistance and other properties. Water based polyurethane dispersion (PUD) refers to polyurethane dispersion without emulsifiers, also known as polyurethane dispersion. It features high flexibility and excellent coating and adhesion on high-performance substrates such as wood, cement, metal, plastic, paper, textiles and rubber, and can be widely used in automotive base paint and touchdown paint. The coating fields include primers and colored coatings, wood and furniture coatings, durable floor coatings, etc., as well as textile coatings, shoemaking, papermaking, adhesives, etc. In recent years, with the rapid development of water-based coatings as substitutes for solvent-based coatings, the market size of water-based coatings has also been continuously expanding. The expansion of the water-based coatings market will drive the growth in the application demand for water-based polyurethane dispersions in the coatings field. Coatings based on waterborne polyurethane dispersions will become the preferred choice in fields such as wood, leather, automobiles, construction, metals, furniture, plastics, and decorative glass. Sinograce Chemical is developing a variety of superior and more sustainable water-based product systems to replace solvent-based products and meet the diverse needs of more users. From this perspective, Sinograce Chemical will create new growth opportunities for itself by developing customizable PUD products and increasing the output of waterborne polyurethane dispersions. In addition to the fields of coatings and adhesives, waterborne polyurethane dispersions can also be used in the coating of textiles and the production process of fiber-reinforced plastics. In the field of textile coatings, waterborne polyurethane dispersions can endow textiles with better wear resistance, flexibility, cleaning resistance and other properties. In the future, as the production scale of coated fabrics further expands, the application volume of them in textile coatings will increase significantly, which will also indirectly drive the demand scale for polyurethane dispersions. Waterborne polyurethane dispersions are important auxiliary materials in fields such as coatings and adhesives. With the continuous improvement of global environmental protection requirements and standards, waterborne polyurethane dispersions that do not contain VOC or have extremely low VOC content will meet the requirements of more and more countries and regions for the environmental protection and greenness of industries. Waterborne polyurethane dispersions will also enjoy a broader development space.

read more

English

English français

français русский

русский español

español العربية

العربية