What is the paper coating material? Application and function analysis

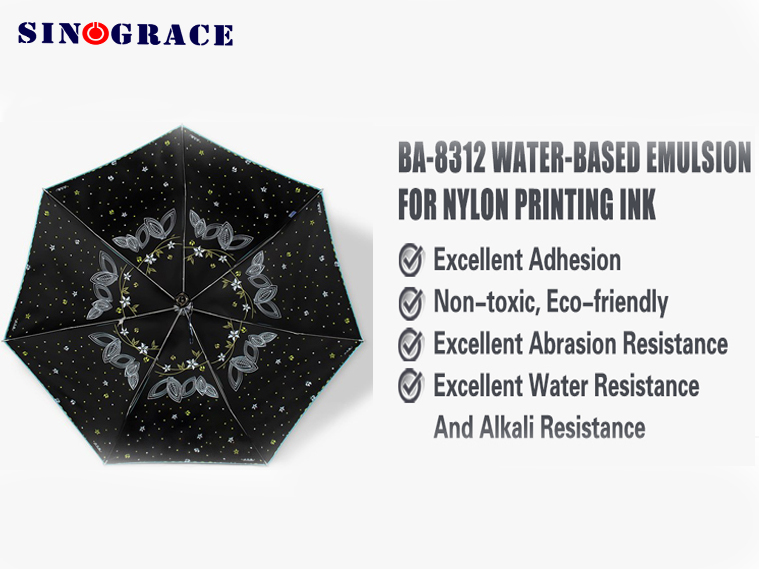

First. Application of paper coating Paper coating is mainly used in packaging printing, book printing, poster printing and other fields, which can improve the gloss of paper, waterproof, oil-proof, wear-resistant, anti-folding and other functions. The paper coating can not only improve the quality of the paper, but also enhance the durability, stability and aesthetics of the paper, and is also a solution to meet the needs of environmental protection. Second, the characteristics of paper coating materials 1.Polyethylene: polyethylene has excellent waterproof, oil-proof and moisture-proof properties, so it is often used in paper products that need to be waterproof and oil-proof. Polyethylene coating can be used for imitation copper paper, gold-plated paper, coated paper, etc., beautiful effect is good, and long life. 2.Polyurethane: The use of polyurethane is very wide, it has applications in different fields, such as packaging materials, electronic materials, building materials and so on. Polyurethane coated paper not only has excellent mechanical properties and touch, but also has low friction, anti-static, excellent oil resistance and water resistance and many other advantages. 3.Polypropylene: polypropylene moisture-proof, waterproof, oil-proof performance is good, so that it is widely used in packaging materials, office stationery, building insulation and other fields. Polypropylene coated paper is light in texture, easy to process and carry, and can also protect against moisture, water, oil and sun. Third, the role of paper coating 1.Improve the beauty of the paper: the surface of the paper coating is smooth, high gloss, and has a good color reduction and printing effect. This is critical in areas such as book and poster printing. 2.Enhance the durability of the paper: After the paper coating, the hardness, wear resistance, folding strength and other properties of the paper have been greatly improved, which enhances the strength and stability of the paper, and also extends the life of the paper 3.Improve packaging quality: After the paper coating, the toughness of the package increases, making the package more firm. At the same time, the paper coating makes the packaging material have higher moisture, water, oil, folding and other properties, and better protect the quality and safety of the internal items. In summary, paper coating is a special material that can improve the characteristics, aesthetics and protection of paper, and has a wide range of applications, and its commonly used coating materials include polyethylene, polyurethane, polypropylene and so on. Coated paper has better durability and other properties, which plays an important role in packaging, printing and building materials. Sinograce Chemical produces all kinds of water-based coatings for paper, top coating and primer, and various additives and viscosifying emulsions.

read more

English

English français

français русский

русский español

español العربية

العربية