Study on the characteristics and application of water-based pressure sensitive adhesive

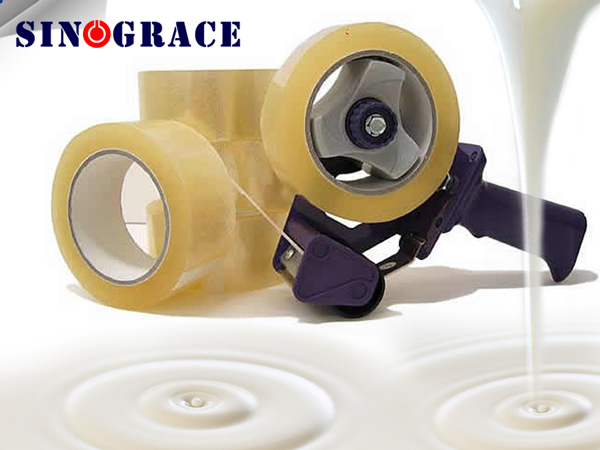

Water-based pressure-sensitive adhesive is a type of adhesive that uses water as a solvent and is pressure-sensitive, that is, it can adhere quickly to the surface when slight pressure is applied. Due to its environmental protection, non-toxic, cost-effective, adjustable viscosity and other advantages, it has gradually become the mainstream product in the pressure sensitive adhesive market. According to different systems, water-based pressure sensitive adhesive is divided into water-based acrylate system, water-based polyurethane system, water-based latex system and water-based silicone system, etc., which is the most widely used because the water-based acrylate system has a wide adjustable range of performance, rich application scenarios, and high cost performance characteristics. Characteristics of water-based pressure sensitive adhesive 1, strong adhesion: Water-based pressure sensitive adhesive can form a uniform adhesive layer on different types of substrates, compared with other chemical adhesives, its adhesion is stronger, and can cope with different conditions, such as temperature, humidity, etc. 2, drying fast: water-based pressure sensitive adhesive solid content is relatively high, easy to volatilization in processing, drying time is fast, high processing efficiency. 3, Environmental protection: the preparation of water-based pressure sensitive adhesive does not require the use of organic solvents, reducing environmental pollution and safety risks, with low volatility and low VOC content. Application of water-based pressure sensitive adhesive 1.labels and stickers: such as self-adhesive labels, post-it notes, decorative stickers, body stickers, etc. 2.Medical tape/dressing: such as band-aid, dressing, surgical dressing, etc. 3.industrial tape: such as a variety of pressure sensitive tape, transparent tape, BOPP film tape, duct tape, double-sided tape, foam tape, sealing tape, paper tape, high temperature tape, etc. 4.plastic film class, such as PE, PP, PVC and polyester film. In addition, water-based pressure sensitive adhesive can be applied to a variety of substrates (such as foam, non-woven fabrics, nylon fabrics, etc.) self-adhesive processing, shoe materials, paper products, etc., can also be used for high-grade crafts processing, special paper products. For these specific applications and different coating methods, Intron has developed a number of water-based pressure-sensitive adhesives, each with a different solid content and viscosity to suit their specific use. 5.Make up and protect yourself 6.A kind of water-based pressure sensitive adhesive system made by special synthesis process and formula combination can also be used in beauty care scenes, with skin-friendly effect to prevent allergies. Water-based pressure sensitive adhesive (Universal)

read more

English

English français

français русский

русский español

español العربية

العربية