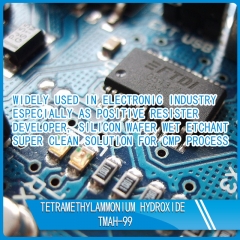

Tetramethyl ammonium hydroxide TMAH-99

Typical properties CAS No.: 10424-65-4 Chemical formula: (CH3)4NOH·5H2O Molecular weight: 181.15 Melting Point(℃): 63 Form: White solid powder Purity (%): >99.5 Boiling Point (℃): 100.0 Freezing point (℃): <-25.0 Viscosity@ 25℃, cst: 2.8 Specific Gravity @ 20℃: 1.021 Flashpoint (Pensky Martens), °F: >95 pH: >13 Application -The catalyst of dimethyl silicone oil, benzyl methyl silicon oil, organic silicon diffusion pump oil, solvent-free silicon molding plastics, silicon rubber for organic silicone resin. -Ash-free alkali for precipitating lots of metal elements. Brightener cleaner and touch cutting agent for computer silicon wafer surface during the production of silicon wafer. -Widely used in electronic industry, especially as positive resister developer, silicon wafer wet etchant and super clean solution for CMP process. Also used in the manufacture of integrated circuits, liquid crystal displays, printed circuit boards, capacitors, sensors, and many other electronic components. Storage and handling Available in 25 kg/drum Store products in tightly closed original containers at 5-40℃ Shelf life: 12 months from delivery date According to non-dangerous goods transport

read more

English

English français

français русский

русский español

español العربية

العربية