Bond strength and deinking

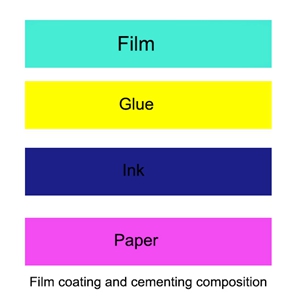

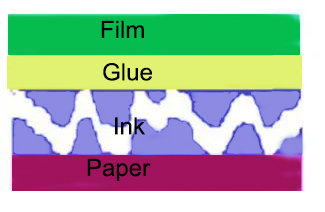

Bond strength is one of the most important indexes of glue properties. Bond strength refers to the amount of force required when the film and paper are stripped, and this index is often combined with the deinking effect. We first need to understand the principle and structure of paper-plastic composite.

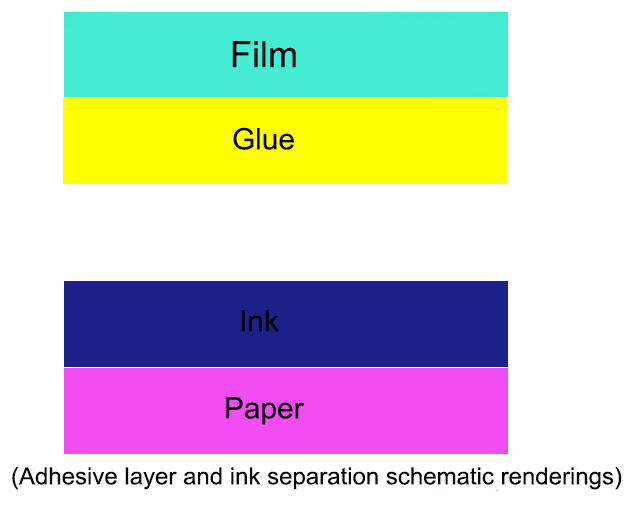

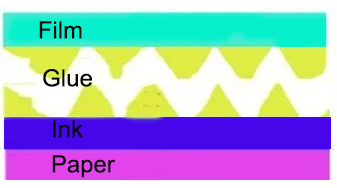

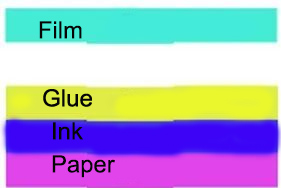

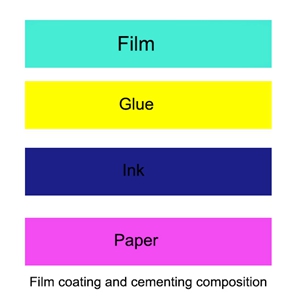

If you want to enhance the bonding force, you must consider the rationality of the bonding force of each layer. As can be seen from the figure below, the composite bonding force mainly includes:

1) Adhesion between ink and paper

2) Adhesion between adhesive layer and ink

3) Adhesion between film and adhesive layer

Relationship between various peeling effects, adhesion, and deinking

▲Peel off completely from the paper and deink completely

When completely deinking, there are often two situations, one requires a stronger peeling force, while the other is completely opposite, only a lower peeling force is required to completely deink, the main reason for these two different results is The reason is the difference of paper.

1. The peeling strength is high, which means that the bonding force of the other two layers is greater than the bonding force of ink and paper, and the effect is better. This is also the best composite effect pursued by most composite manufacturers.

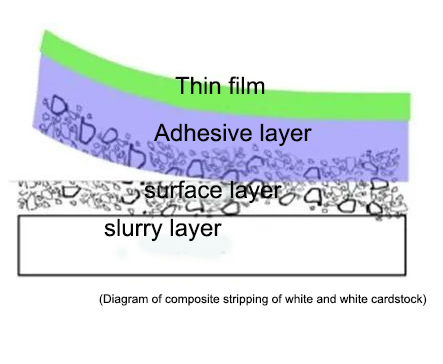

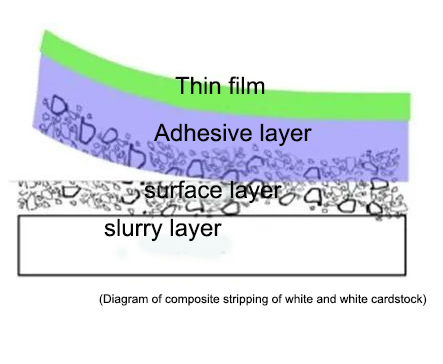

2. The peeling strength is low. One reason is that the bonding force between ink and paper is poor, or the ink has false drying phenomenon. The more reason is that the surface of the paper is loose, which is especially common in the compounding of gray and white cardboard.

The surface layer of gray-white cardboard has a lot of fillers. If the glue cannot completely penetrate the surface layer and combine with the slurry layer after compounding, it will occur on the surface layer during peeling, and the peeling force required at this time is very small.

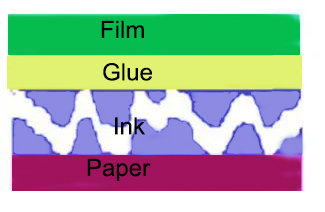

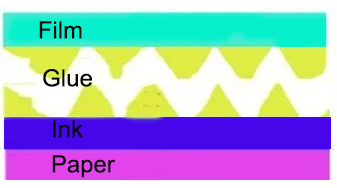

▲The ink layer is disconnected, part of the ink is on the film, and part is left on the paper

(Partial deinking schematic renderings)

This peeling state should be the most ideal peeling effect, indicating that the bonding force of each layer is very good.

But pay attention to the situation of gold and silver ink, the surface layer of gold and silver ink is very similar to gray and white cardboard, it is composed of copper powder or aluminum powder and some binders, its internal structure performance is not very good, the ink layer is relatively loose, peeling off It is easy to separate during the period, and the peeling force is very small.

▲The adhesive layer is separated from the ink layer without deinking

This situation shows that the adhesion between the adhesive layer and the ink layer is insufficient and the effect is poor. There are several reasons for this situation:

1) The glue is very hard, especially the summer glue is used in winter.

2) The temperature and pressure of the pressure roller are not enough during compounding, so that the glue cannot fully deform and penetrate into the ink layer.

3) The surface tension of the ink is too low, especially when too much drying oil is added in winter.

4) If the paper is left for too long after printing, the ink will age and crystals that are difficult to bond will be formed on the surface.

▲The adhesive layer is broken

(Schematic diagram of adhesive layer separation)

When peeling off, it is disconnected from the adhesive layer, leaving an adhesive film between the film and the paper, accompanied by a long drawing phenomenon, the composite rigid

This often happens when disembarking. This situation shows that the glue film is not good or the cohesion is not enough, and the effect is poor.

There are several reasons for this:

1) The glue drying effect is not good, and the glue layer still has a lot of water

2) Peel off when the glue is not fully cured. At this time, the glue has not reached the best state and is in a relatively tender state

3) In some high-grade glues, some external linking agents are often added. These cross-linking agents need to react and work under certain temperature conditions to enhance the cohesion of the adhesive layer. If the temperature of the pressing roller is low, often Incomplete or even no reaction of these cross-linking agents will not only prevent the cohesion from being improved, but also reduce the cohesion due to the presence of these substances. In this case, the adhesive layer will also break.

▲The film is separated from the adhesive layer without deinking

There are also two situations in which the film and the adhesive layer are separated, one is that the peel strength is high, and the other is the opposite, and the peel strength is low.

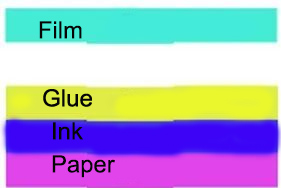

(Diagram of demoulding and adhesive effect)

1) The peel strength is high, which means that the bonding force between the adhesive layer and the ink layer is greater than the bonding force with the film, which often occurs when the glue is soft. The glue is soft, has good deformation ability and penetration ability, and can penetrate into the ink layer or even the paper layer, greatly improving the bonding strength, which exceeds the original relatively good bonding force between the adhesive layer and the film. separated from the film. In this case, it is necessary to pay attention to the processes with deformation operations such as die-cutting, embossing, and embossing. Because these processes deform the film, the film produces a resilience to restore its original shape, and the glue is soft. Tensile fracture is easy to occur under the action of the glue, resulting in degumming and blistering.

2) The peel strength is low, which means that the combination of the adhesive layer and the film is abnormal due to some factors. Generally, there are the following situations:

■ The corona value of the film is not enough, and materials with low surface tension are difficult to bond, so if the corona value of the film is low, it will greatly affect the bonding force during the period, and the purpose of corona is to increase the tension value of the surface layer of the film, so generally The film requires a corona value ≥ 38 dynes.

■ The glue has not dried out or the moisture has not evaporated after pasting. The presence of these moisture will affect the adhesion of the adhesive layer.

junction performance

■ If the ambient temperature is too low, the glue will harden and the bonding performance will decrease. This is especially easy to happen when summer glue is used in winter.

Solid content

The solid content is the percentage of the remaining part of the emulsion after drying under specified conditions. The level of solid content can not fully explain the bonding performance of the glue. High solid content is a condition for the high performance of glue, but it cannot be simply reversed to think that the performance of glue with high solid content must be good.

The level of solid content can roughly understand the amount of active ingredients in the glue, and affect the drying speed of the adhesive, powder covering ability and product brightness after film coating.

Effect of solid content on drying speed

Generally speaking, the higher the solid content, the less moisture needs to be volatilized, and the faster the drying speed. But the drying speed is affected by the glue solvent and PH value, which is why sometimes the glue with high solid content is not as fast as the glue with low solid content.

Influence of solid content on cap powder

Although the glue with high solid content is helpful to improve the composite brightness, its influence is not decisive. The brightness is mainly a comprehensive reflection of the transparency of the glue itself and the composite filling effect. However, the brightness of the glue with low solid content after compounding is generally not good.

Determination of solid content

The determination of solid content is mainly to determine the amount of mass reduction after the adhesive is placed in an oven at a specified temperature.

The difference between effective content and solid content

From the method of measuring the solid content, it can be seen that the actual solid content is the amount of the remaining substances after the volatile substances are removed, and the volatile substances in the actual glue are not completely water, and some substances are also volatile. also plays an important role. Such as pH regulators and plasticizers, these substances are not included in the range of solid content, so we can include them in the effective content.

3. PH value

The PH value is also called the hydrogen ion concentration index, which is the concentration of hydrogen ions in the solution. In layman's terms, it refers to the acidity and alkalinity of the glue.

The Effect of PH Value on Viscosity

The influence of adjusting the pH value of the adhesive on the viscosity is very obvious. The viscosity of the glue is low under acidic conditions, and the viscosity will increase as it changes to alkaline.

In the actual application process, if you feel that the viscosity of the glue is low and the gluing effect is affected, you can increase its viscosity by adding ammonia water. It should be noted that the smell of ammonia water is strong. When used in summer or in poor ventilation, it will affect the working environment. It is not possible to change the glue with a lower viscosity into a glue with a higher viscosity by adding a large amount of ammonia water one-sidedly. of glue.

Effect of PH value on mechanical stability

In the case of partial acidity, the performance of the glue is unstable, and the storage stability will become poor, and there will be agglomeration, delamination or even demulsification. So this also requires the pH value of the glue to be adjusted to neutral and slightly alkaline.

When the temperature is high in summer, there may be a problem that the PH value of the glue changes due to the volatilization of ammonia water, thereby affecting its viscosity and storage stability. At this time, it is necessary to add an appropriate amount of ammonia water or other PH value regulators.

Effect of PH value on gold and silver ink

Gold and silver inks are mainly copper powder and aluminum powder. Excessively high acidity and alkalinity will cause oxidation reactions to cause discoloration. Therefore, the pH value of the glue used for compounding gold and silver ink prints should be close to neutral.

Determination of PH value

The determination of PH value can be carried out by test paper colorimetry and instrument measurement method, among which the test paper colorimetry is simple and fast, and is a commonly used determination method.

Sinograce chemical production of Water-based Laminating Adhesive, welcome to consult.

English

English français

français русский

русский español

español العربية

العربية