Anti -deformation power

Anti -deformation capacity refers to a certain deformation after the composite product is affected by external forces, and this deformation will produce a certain amount of elasticity, especially the thin film. If the combination of composite is not enough to resist the elasticity of the return, foaming will occur, etc. Happening. There are many processes that produce deformation, such as pressure lines, uneven, mold cutting, etc.

The ability to resist deformation of glue is often contradictory with bonding performance, so why does it have contradictions? First look at this problem from the hard and hard relationship between glue.

■ Comparison of adhesive hard and hard performance

By adjusting the types and ratio of raw materials in the formula of adhesive products, the glue can have different soft and hard characteristics.

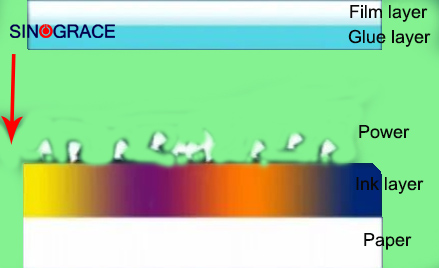

(Drawing effect diagram of soft and hard rubber layer)

Generally speaking, the bonding properties of glue are affected by its hardness and softness. The glue is soft, it has high viscosity, but under the action of external force, it is easy to deform and draw wire, resulting in the fracture of the adhesive layer.The hard glue is not too deformation and fracture, but the bond strength decreases. So glue is looking for a suitable range between soft and hard.Soft glue has good initial viscosity, strong deformation and permeability, but low tensile strength, easy to break, so it is prone to problems in embossing and die cutting. The hard glue has high tensile strength, but poor viscosity, and the stripping strength will be weakened after the film is covered.

The degree of softness and hardness of glue will be affected by temperature. When the temperature is higher in summer, the glue has soft characteristics, and when the temperature is lower in winter, it has hard characteristics.

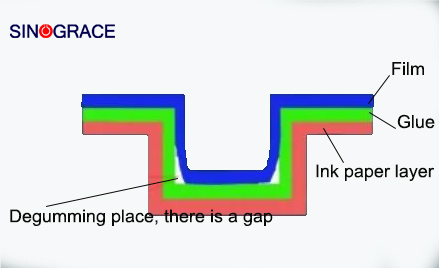

(Effect diagram of separation of film and adhesive layer)

After understanding the relationship between the degree of soft and hard glue and the bonding force and the ability to resist deformation, we can carefully discuss the deformation of composite products.

■ Separate the film from the adhesive layer

This situation shows that the glue and film have insufficient adhesion or soft glue. It seems that these two situations are a bit contradictory, and they are actually extreme phenomena in two situations.

★ Insufficient adhesion for glue and film

We have talked about the reasons why the film and glue adhesion are insufficient. The main is the insufficient film, the presence of water, and the low environmental temperature causes the glue to be strong.

★ Glue is too soft

If the glue is soft, it is easy to cause the glue layer to rose and break it. This situation is prone to occur in high temperatures in summer. The environmental temperature is high, and the performance of the rubber layer will be transferred to a soft direction. Therefore, this situation will occur if it is used in summer in summer.

(Details of the separation effect of the film from the film)

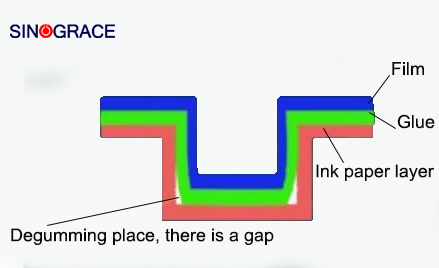

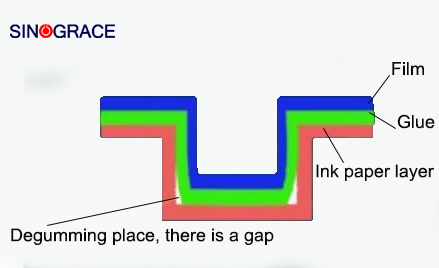

■ Adhesive layer and ink deinking

This situation shows that the glue and ink adhesion is insufficient. The cause of this problem also mentioned earlier, mainly in the four aspects: strong glue, insufficient temperature of pressure rollers during composite Low, paper is printed for too long.

(Effect diagram of the split layer and ink)

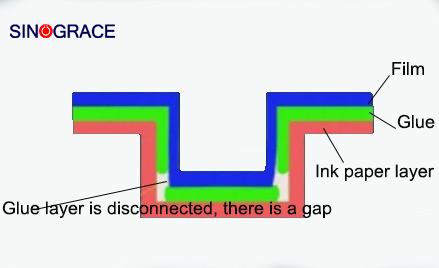

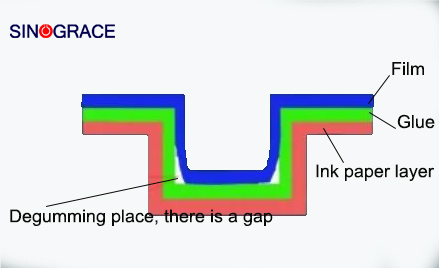

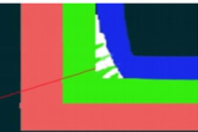

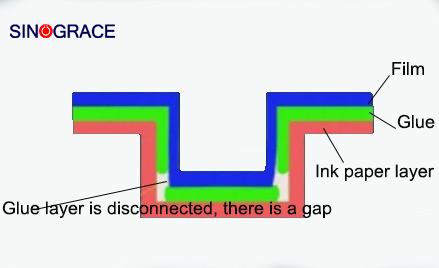

■ Glip layer disconnection

This situation shows that the glue is too soft, excessive or insufficient in glue, and the glue layer is not completely solidified

★ Globe is too soft or too strong

After the external force is affected, the composite material has the characteristics of extension, and the stratum corporate must also have corresponding extension. If the glue is too soft, the phenomenon of brushing and break is caused by extension and rebound. In this case, there is often no response after transformation processing, and foaming will appear after a period of time; and when the glue is too strong, when the external force is extended, the glue layer lacks the corresponding deformation ability and directly breaks. It is a problem that will occur while deformation processing

(Effect picture of adhesive layer disconnection)

★ Insufficient glue

If the amount of glue is low, there is no sufficient rubber layer in the process of extension at the same time as the film extends at the same time, causing the phenomenon of gluelessness in the middle, and it also manifested as a foam. Therefore, for products with deeper compression and bumps, there must be a large amount of glue.

★ Dipping off when the glue is not completely solidified

After the glue has just reinforced, it is in a relatively tender state. It takes a certain time to solidify it to achieve the best state. If it is immediately mounted, it will cause the rubber layer to break.

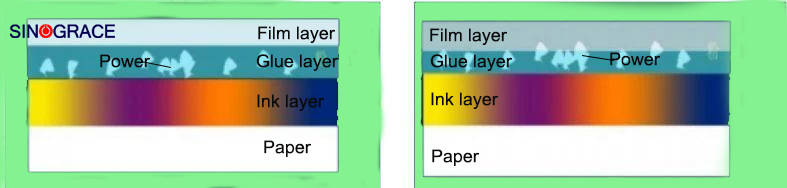

Seven, covering powder

In order to adapt to multi -color high -speed printing, the glue printing process is often used to solve the disadvantages of the back dirt. Most of the powder spraying is composed of grain starch and natural suspended substances. The anti -adhesive effect of the spray spray is mainly formed a layer of irreversible cushion on the surface of the ink layer.

(Effect picture of lid powder)

Because of the coarse particles, if the printing process of powder spraying too much, these particles float on the surface of the printed matter, the adhesive is not every place and ink layer bonding, but with this layer of powder bonding, resulting in false adhesion phenomenon, seriously affect the quality of the film. If the glue layer does not fully contain the powder, the glue will form a blank where there is powder.

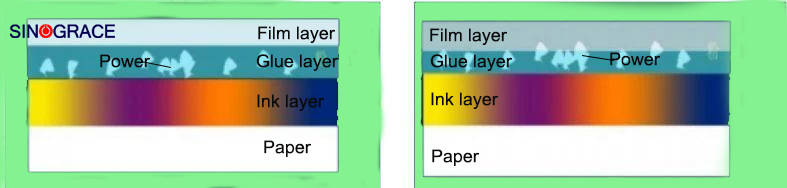

(Excellent effect of covering powder) (The effect of covering powder is poor)

There are the following ways to achieve a good effect of covering powder:

1) Using high -solid glue

2) Increase the amount of glue

3) Dry the paper with a lot of powder spraying

In the actual operation, some film covered products are white -haired, and they are often said to be poorly covered, but the phenomenon is not completely difficult to cover. For example Poor coating, also pinhole, bubbles, etc.

English

English français

français русский

русский español

español العربية

العربية