Classification of waterborne polyurethane coatings

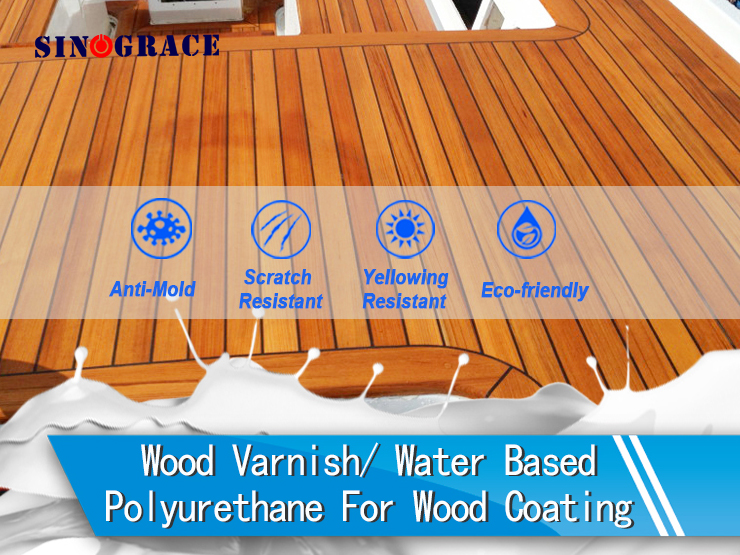

(1)Paint for transportation vehicles cars, ships, aircraft and other transportation vehicles, in addition to meet the requirements of gloss, friction resistance, adhesion, etc., due to its special frequency of use and environment, the waterproof performance of waterborne polyurethane coatings used is also put forward high requirements. The water-based polyurethane waterproof coating referred to here is mainly used in the internal parts of transportation vehicles (such as car dashboard, air bag surface layer, etc.), repair paint, ship painting paint and other aspects. (2)The application of waterborne polyurethane waterproof coating in the field of building waterproofing includes roof, interior and exterior walls, basement and other waterproofing. Bathroom, lavatory, kitchen and other indoor waterproof; Water proofing of storage tanks, swimming pools, roof gardens, roof fish ponds, etc. Subway, underground buildings, underground pipelines and other waterproof and anti-corrosion; Joint shrinkage, sealing and other waterproofing of concrete members; Airtight warehouses, roads, Bridges and other waterproofing. In addition to its high waterproof performance, it also needs to meet the following special properties: suitable for the surface construction of various complex shapes of the base; The elongation at break is large, which can adapt to the expansion, contraction and cracking of the substrate surface; According to the selection of construction substrate, it has good adhesion with PC hard bubble, steel, asbestos, ceramics, bricks, cement, stone, etc. There are no holes after film formation to avoid dust accumulation. (3)Wood paint Because wood products in contact with water are easy to produce obvious defects such as discoloration, expansion, cracking and so on, which will affect its use utility and service life, waterborne polyurethane wood paint has high requirements for waterproof performance. At the same time, the paint film is not easy to deform and fall off after being pressed by heat or heavy objects, resistant to scratches and collisions, high gloss and transparency, and not easy to yellowing. In addition, sometimes it is necessary to meet the special process effects of some wood products, such as ripples, folds and so on. (4)Fabric coating Waterborne polyurethane can be widely used in nylon yarn, silk, cotton, canvas, polyester cotton and other fabrics coating. The fabric finished by the waterborne polyurethane waterproof coating should have the functions of water resistance, moisture permeability, soft surface and elasticity. Waterproof and permeable fabric is also called "breathable fabric", which can only pass through water vapor molecules, not through water droplets, and integrates waterproof, permeable, windproof and warm properties in one fabric, which can resist the invasion of rain and cold wind, and allow the sweat of the human body to be expelled in time. (5)Leather finishing agent Leather finishing agent can increase the beauty a...

read more

English

English français

français русский

русский español

español العربية

العربية