Product Detail

|

Composition

|

|

Chemical Name

|

UV curable hot melt pressure sensitive adhesive

|

|

Type (single product or mixture)

|

mixture

|

|

Chemical name of main components

|

Content(%

|

|

Acrylic ester copolymer

|

≥99%

|

|

Ethyl acetate

|

≤1%

|

1. Application

This product is suitable for substrates such as MOPP, OPP, PET, PP synthetic paper, PP, etc. The adhesive force is adjustable from 200g to 400g/25mm, and the long-term temperature resistance can reach over 80 ℃

2. Performance

This product is suitable for substrates such as MOPP, OPP, PET, PP synthetic paper, PP, etc. It can be used as an adhesive for protective films and can be used for the coating of low weight pressure sensitive adhesives.

3.1 Composition of test pieces

----- Substrate:50μm PET film

-----Adhesive: 25μm dry

----Release paper: Double sided silicon isolation paper

3.2 Curing condition

Use the UVC band to solidify it.

3.4 UVUV curing mechanism

The photoinitiator in UV glue generates free radicals to take hydrogen and form cross-linking in the UVC band.

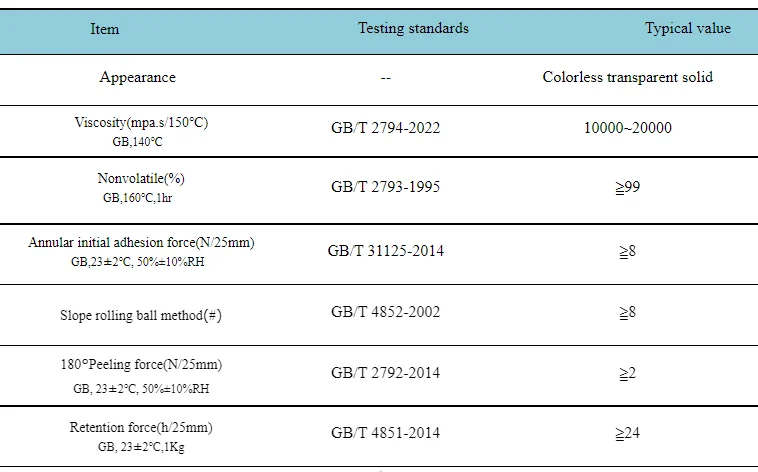

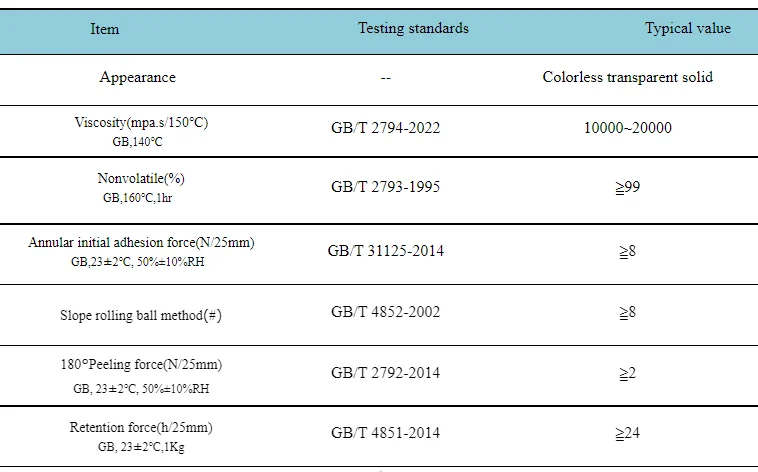

3.4 Physical and chemical indicators

![]()

4. Precautions during coating

4.1 This adhesive cannot be mixed with other adhesives. Before use, clean the container, glue pump, glue delivery pipe, and coating head.

4.2 This product is a UV cured hot melt pressure-sensitive adhesive, which is a solid state at room temperature. Care should be taken to avoid light during transportation and storage.

4.3 Glue thickness: Apply according to customer requirements.

4.4 This adhesive is mainly used as a protective film adhesive and can be used for the coating of low weight pressure sensitive adhesive.

4.5 Adjust the energy according to the adhesion requirements, and the specific curing energy can be referenced based on the following data.

|

Energy mj/cm2

|

180°Peeling force /N

|

Annular initial adhesion /N

|

Holiding power/25℃/h

|

Thickness/μm

|

|

25

|

4

|

8

|

≥24

|

25

|

Remark:The substrate for this test is a thickness of 50 μ The PET of m is coated directly;

This data is for reference only, and specific data needs to be measured according to customer needs.

4.6 The curing of UV hot melt adhesive is closely related to the UV lamp energy and coating speed. The substrate used for coating is different, and the energy and speed also need to be adjusted accordingly.

4.7 Heat the pressure plate glue machine to around 150 ± 10 ℃ and insert it into the glue box to prepare for coating.

4.8 Temperature requirements for coating head: specific adjustments will be made based on equipment and process conditions.

4.9 Coating speed: Adjust according to the adhesive thickness and UV lamp energy.

5. Maturation of adhesive tape

To achieve a stable performance of the adhesive and to approach the maximum cohesive strength of the adhesive, the coated tape must be tested, processed, or used after 24 hours of storage.

6. Adhesive storage

The validity period of this adhesive is six months, with a storage temperature of 25 ± 5 ℃. It should be stored in a well ventilated, dry and cool place, and be careful not to expose it to light.

English

English français

français русский

русский español

español العربية

العربية