Product Detail

Description

High concentration printing thickener TH-60 is developed for thickening pigment printing on cotton as well as synthetic textiles. Very quick thickening effect and high electrolyte stability in pigment printing system.

The thickener is a typical thickener that provides viscosity at high shear rates compared to traditional waterborne thickeners, and the thickened system is more efficient in molding, paintability, edge coverage and apparent performance were improved. It has little effect on low and medium shear viscosity. After addition, the apparent viscosity and sag resistance of the system are almost unchanged.

Acrylic copolymer, water-based thickener

Type

Anionic inverse polyacrylate emulsion

An efficient thickener for waterborne VOC-free acrylic copolymers

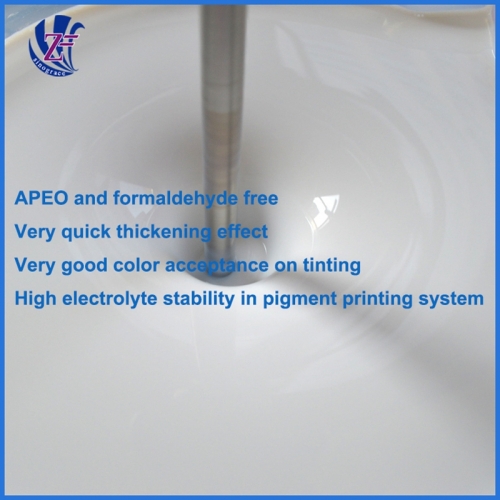

Key features

APEO and formaldehyde free

Very quick thickening effect

Very good color acceptance on tinting

High electrolyte stability in pigment printing system

High concentration anionic inverse polyacrylate emulsion

Suitable for thickening pigment printing on cotton as well as synthetic textiles

Primarily to increase viscosity at high shear rates, resulting in products with Newtonian-like rheological behavior.

Typical properties

Appearance: Milky white

Solid content (%): 60±1%

Density (g/cm3): 1.12

pH (1% in dist. water): 6-8

Application

-Pigment printing

-Textile printing etc.

Recommended dosage: 0.5-3% based on the weight of the formulation The increase in high shear viscosity is a function of the amount added, the exact amount depending on the rheology required for the particular coating.

Application Method

It can be added to abrasive slurries. Ideal results can also be obtained when post-adding in the pre-painting stage. In this case, care should be taken to check the compatibility of the coating system, due to the extremely high polymer particle surface. Therefore, it may cause coagulation or flocculation due to excessive local interaction. If this phenomenon occurs, it is recommended to dilute it with water in advance, such as diluting to a concentration of 10% before use.

Storage and handling

Available in 25 kg/barrel or 200kg/barrel

Store products in tightly closed original containers at 5-40℃

Shelf life: 12 months from delivery date

According to non-dangerous goods transport

English

English français

français русский

русский español

español العربية

العربية