- Home

- About Us

- Products

- Nano coating

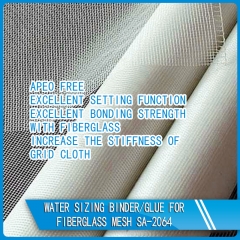

- Water based adhesive

- Printing ink area

- Non Stick Coating

- Acrylic emulsion

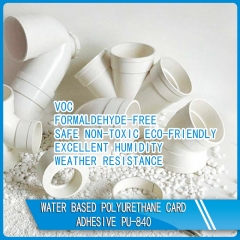

- Water based PU

- Chemical additives

- Chemical raw materials

- Copy rubber products & raw material

- Special Coating/ Resin

- Other products

- Hot Sell Products

- Fluorochemical

- Colorant

- Hot Melt Glue

- Water Based Barrier Coating

- News

- Contact Us

English

English français

français русский

русский español

español العربية

العربية