you may only understand the label do not understand the sticker!

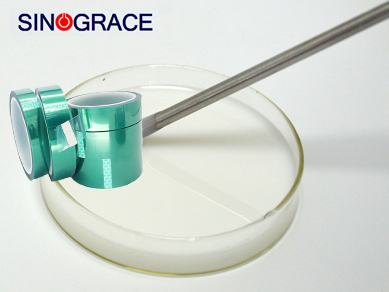

Label is used to show the relevant instructions of the product of the printed matter, some are on the back of the glue, but there are some printed matter is not with glue, glue label is known as "self-adhesive label". Self-adhesive label is a kind of material, also called self-adhesive material. It is a composite material made of paper, film or other special materials, coated with adhesive on the back and coated with silicon protective paper as the base paper. Self-adhesive is a general term for materials with such properties. The market demand for high-grade labels is increasing day by day, domestic has been able to process all kinds of high-grade labels, previously processed in overseas labels have gradually turned into domestic production, which is also one of the main reasons for the rapid development of domestic label printing. Application of self-adhesive labels As a form of packaging to achieve appearance and specific functions, self-adhesive labels can be flexibly applied in all walks of life. At present, the label in the pharmaceutical industry, supermarket logistics industry, electronics industry, lubricating oil, tire industry, daily chemical, food, clothing and other industries have superior application! Self-adhesive labels are roughly divided into two kinds: one is the paper self-adhesive label, the other is the film self-adhesive label. 1.Paper self-adhesive labels are mainly used in liquid washing products and popular personal care products; Thin film materials are mainly used in high - grade daily chemical products. At present, popular personal care products and household liquid washing products occupy a large proportion in the market, so the corresponding paper materials are used more. 2.Film self-adhesive labels are commonly used in PE, PP, PVC and some other synthetic materials. The film materials are mainly white, matte and transparent. Because the printing adaptability of thin film material is not very good, it is generally treated with corona or by adding coating on its surface to enhance its printing adaptability. In order to avoid the deformation or tear of some film materials in the printing and labeling process, some of the materials will be subjected to directional processing, one-way stretching or two-way stretching. For example, BOPP materials with two-way stretching are widely used. The structure of the sticker In the usual sense, we call the structure of self-adhesive label "sandwich" structure: surface material, glue (adhesive), the bottom paper, the three layers of structure is the basic structure, but also we can see the naked eye. In fact, many materials may be divided into more detailed, for example, some film surface and coating, easy to print, some materials and glue between the coating, easy to material and glue full combination and so on. The production process of self-adhesive label Simply put, the production process of self-adhesive label materials is completed by coating and composite two processes. The...

read more

English

English français

français русский

русский español

español العربية

العربية