Do you know anything about laminating glue?

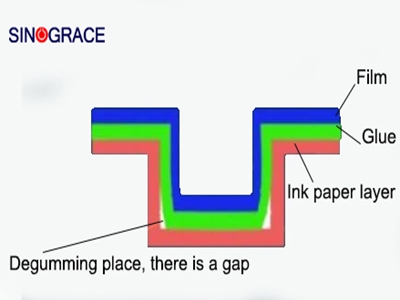

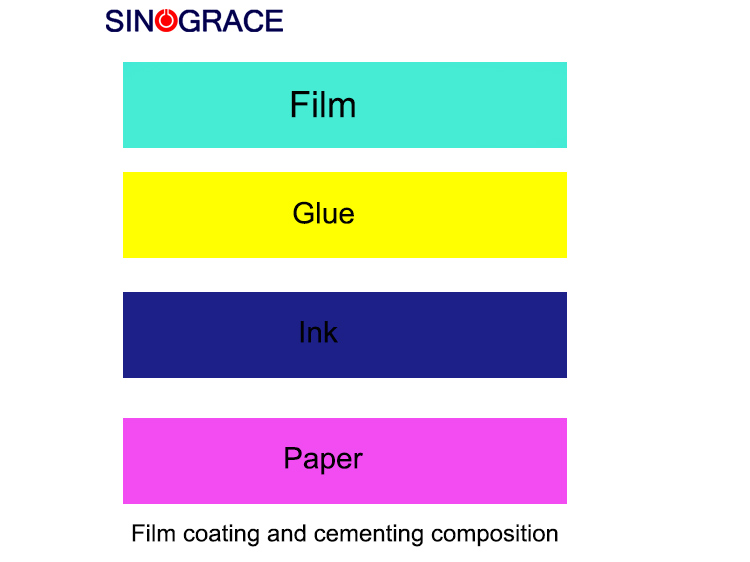

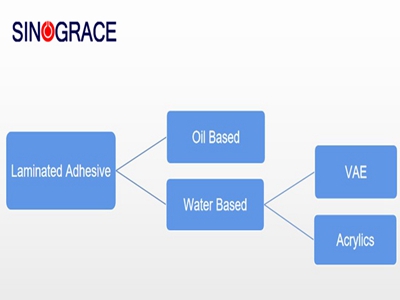

Hot melt adhesive (English name: HotGlue) is a kind of plastic adhesive, in a certain temperature range, its physical state changes with the change of temperature, but the chemical properties remain the same, its non-toxic and tasteless, belongs to environmental protection chemical products.Because the product itself is solid, easy to package, transport, storage, no solvent, no pollution, non-toxic type; As well as simple production process, high added value, bonding strength, fast speed and other advantages are favored. Environmentally friendly water-based adhesive is environmentally friendly. Water-based coated adhesive is a way to process the surface of printed matter, improve the gloss and strength of the surface of printed matter, and enhance the aesthetic effect. To measure the quality of the film, it is also necessary to examine its brightness, strength, bonding force and so on. Waterborne wet laminating is characterized by its high strength, easy recovery, no pollution and so on. To this end, we launched our own water-based film adhesive! Definition and classification of laminating adhesives Laminating glue refers to PET, BOPP film composite on the paper of a kind of glue. In the post-press process of the printing and packaging industry, the film coating improves the brightness of the printed matter, enhances the water resistance, makes the ordinary paper have the advantages of film and paper, and provides a beautiful visual effect for the packaging. Laminating adhesive includes water and oil - based two. In the domestic now water-based coating adhesive, most of the water-based acrylic emulsion system. Classification of laminating adhesive 1. According to chemical properties 2. According to the composite process Wet composite and dry composite Wet composite although the machine covers a small area, less power consumption, simple operation, but the finished product of the composite toughness is poor, poor adaptability to gold and silver ink, high-grade products simply cannot meet the requirements, with the maturity and perfection of water-based dry coating adhesive, people are more and more like to use water-based adhesive dry composite. 3. According to the printing method Lithography and intaglio printing Lithography is characterized by ink printing on paper and glue coating on the corona side of the film. At present, paper - plastic composite is mainly offset printing. This kind of compound equipment is relatively simple, compound speed is slow, gluing amount is large. There are two ways of gluing on mirror roller and mesh roller. Gravure printing is mainly characterized by ink printed on the film, glue coated on the film ink side. This way is film and film composite, in the paper and film composite application ratio is not high, but some special paper will use this composite way, this kind of composite equipment is relatively complex, composite speed is fast, less glue, more use of mesh roller glue, glue amount can be adjusted according...

read more

English

English français

français русский

русский español

español العربية

العربية