Classification and properties of water-based adhesives

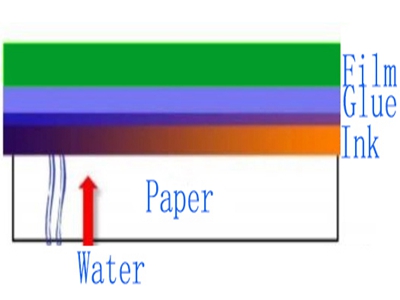

Existing water-based adhesives are not 100% solvent-free and may contain limited volatile organic compounds as additives to their water-based media in order to control viscosity or fluidity.The advantages are mainly non-toxic, no pollution, no combustion, safe use, easy to achieve clean production technology, etc., disadvantages include slow drying speed, poor water resistance, poor frost resistance. PART 01 Classify 1.Classification by material Polyvinyl alcohol water-based adhesives, vinyl acetate water-based adhesives, acrylic acid water-based adhesives, polyurethane water-based adhesives, epoxy water-based adhesives, phenolic water-based adhesives, silicone water-based adhesives, rubber water-based adhesives. 2.Classification by application Water-based adhesive for construction, packaging, automobile, shoemaking, daily use, water-based adhesive. 3.according to the solvent classification Water soluble and emulsion adhesive two kinds. PART 02 Properties and modification of water-based adhesives Waterborne polyurethane (APU) adhesive APU is a new type of polyurethane system in which water replaces organic solvent as dispersion medium, also known as water-dispersed polyurethane, water-based polyurethane or water-based polyurethane. Waterborne polyurethane with water as solvent, no pollution, safe and reliable, excellent mechanical properties, good compatibility, easy to modify. APU adhesive is non-toxic and pollution-free, and its high molecular weight enables it to form an excellent adhesive film. It has the advantages of low temperature resistance, flexibility, good bonding performance and wide adjustable range of the physical property of the adhesive film. Its molecular structure has flexible molecular chain, showing excellent impact resistance, fatigue resistance, low temperature resistance, but also has the performance of designability, the adhesive layer from flexible to rigid arbitrary adjustable, can meet the bonding needs between different materials; At present, the synthesis method of waterborne polyurethane adhesive has been relatively mature. There are mainly the following methods: (1)Introduce some hydrophilic groups into the structure of polyurethane resin to make it self-emulsifying. (2)Acetone method: the high viscosity prepolymer is prepared first, and then acetone is added to reduce the viscosity, and then the hydrophilic monomer is added to the water under high speed stirring, and it is dispersed in the water through strong shear. After emulsification, the decompressive distillation to recover the solvent is prepared PU water dispersion system. (3)End-sealing isocyanate method: select an appropriate sealer, protect the end-NCO group of the water-sensitive isocyanate, make it lose its activity, and then add chain extender and crosslinking agent co-emulsion to make emulsion use, through a certain temperature and special catalyst, regenerated into -NCO end-group, chain extension to prepare waterborne polyurethane. (4)End-sea...

read more

English

English français

français русский

русский español

español العربية

العربية