Product Detail

Description It's fun to look at with colorful electrical appliances houseware and, industrial parts.

Spray Water Borne Silicone Coating For Cookware S-201 is particularly designed for aluminum, steel and other metal mold coatings. It has outstanding stain resistance, non-stick performance and superior abrasion resistance. It has good heat resistant and workable at 300℃.You can also choose from a wide range of our experiences such as home appliance manufacturer, kitchenware, toaster, pot, kettle, cooking tray, and so on.

Type

Solvent based silicone resin

Spray Water Borne Silicone Coating For Cookware

Key features

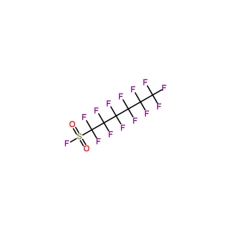

-PFOA free

-Excellent heat resistant

-Excellent chemical resistance and abrasive resistance

-Excellent and lasting non-stick performance, easy to clean

The coated surface protects your valuable home appliances.

Typical properties

Appearance: Yellowish clear liquid

Solid content (%): 34±1

Viscosity (cp): 400~800

Density (g/ml): 1.10

pH: 7.9-10

Color of the film surface: Flat and smooth

Curing temperature (℃): 280-300

Gloss (60° glossimeter): 15-25

Film thickness (μm): 15-20

Corrosion resistance: No blister (Boling 3% HAc for 1 hours)

Abrasion resistance 3KG/21cm2: >20000 cycles

Hardness (ZHONGHUA pencil): 4H-5H

Spray Water Borne Silicone Coating For Cookware

Application

-Aluminum, steel and other metal mold coating

coat requires only primer coat once. Baking(200℃~380℃) is needed after coating

Storage and handling

-Available in 20 kg/ barrel or 30 kg/ barrel

-Store products in tightly closed original containers at 5-40℃

-Shelf life: 9 months from delivery date

-According to non-dangerous goods transport

Non-stick Coating Type

↓ ↓ ↓ Please click product model for more informations

|

Model

|

Layer

|

Thickness

|

Curing temperature

|

Non stick property

|

Anti-corrosion

|

Abrasion resistant

|

|

Water based fluororesin non-stick coating

|

|

PF-600

|

2

|

25-40

|

380-400

|

A A A A A

|

A A A A

|

A A A

|

|

PF-601

|

2

|

25-35

|

380-400

|

A A A A

|

A A A A

|

A A A

|

|

PF-602

|

2

|

25-40

|

380-400

|

A A A A A

|

A A A A

|

A A A

|

|

PF-610

|

3

|

20-35

|

380-420

|

A A A A A

|

A A A A A

|

A A A

|

|

PF-611

|

3

|

20-35

|

380-420

|

A A A A A

|

A A A A A

|

A A A

|

|

PF-612

|

3

|

20-35

|

380-420

|

A A A A A

|

A A A A A

|

A A A

|

|

Water based ceramic non-stick coating

|

|

C-104

|

1

|

30-45

|

280-300

|

A A A A A

|

A A A A

|

A A A A A

|

|

C-105

|

1

|

30-45

|

280-300

|

A A A A A

|

A A A A

|

A A A A A

|

|

C-106

|

2

|

34-50

|

280-300

|

A A A A A

|

A A A A

|

A A A A A

|

|

C-107

|

1

|

12-20

|

250-280

|

A A A A A

|

A A A A

|

A A A A A

|

|

C-108

|

2

|

34-50

|

280-300

|

A A A A A

|

A A A A

|

A A A A A

|

|

C-109

|

2

|

34-50

|

280-300

|

A A A A A

|

A A A A

|

A A A A A

|

|

Silicone resin non-stick coating

|

|

S-200

|

1

|

15-20

|

280-300

|

A A A A

|

A A A A A

|

A A A A

|

|

S-201

|

1

|

15-20

|

280-300

|

A A A A

|

A A A A A

|

A A A A A

|

|

S-202

|

1

|

15-20

|

280-300

|

A A A A

|

A A A A A

|

A A A A

|

English

English français

français русский

русский español

español العربية

العربية